Combined Convertible Development Experience

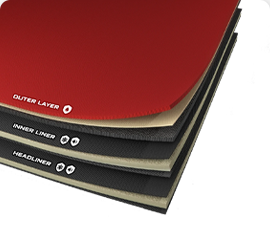

myTops are made from high quality materials and custom engineered to finally let you enjoy your Jeep or Bronco life to the max!

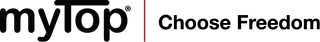

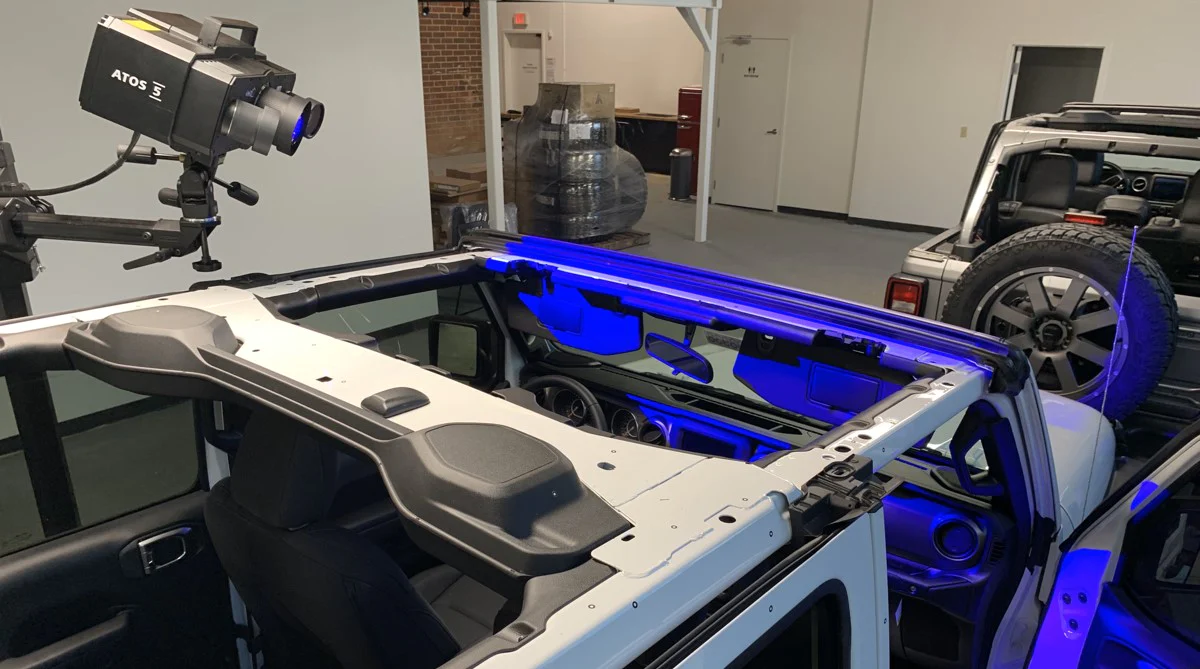

Despite our size and family environment, we have an exceptional international team of experienced industry professionals. The development and creative process is guided from our HQ in Atlanta. The kinematic development is done by an engineering team in Germany, who combine more than 100 years of convertible development experience. The fabric pattern development is done in our manufacturing site in Aguascalientes, Mexico as well as in Atlanta. However, canvas production comes entirely out of Mexico. Final assembly is completed in Mexico or Atlanta, depending on the model. And finally, our global warehouse and shipping are out of our facility in Atlanta.